To the Moon and Beyond, Towards the Future

In the 1980s, Pirelli’s designs benefited from the use of new tools made possible by advances in computing technologies. The following decade saw the development of an important academic partnership with the creation of the Consortium for Research on Optical Switching and Processing in Milan (CoreCom) together with the Politecnico University of Milan. The Consortium soon became a European benchmark for research on optical communications, pioneering work also in networks and special optical fibres. Innovation, however, did not concern materials and products alone. In 1999, at Bicocca, Pirelli presented its Modular Integrated Robotized System (MIRSTM) for automated tyre production. Protected by twenty-two patents, it made it possible to manufacture high- and ultra-high-performance tyres in small batches with very rapid development times, ushering in new logistics and customer service possibilities. This represented a radical shift from traditional production processes. In 2001, the partnership between Pirelli and the University of Milano-Bicocca gave rise to the Consortium for Research on Advanced Materials (CORIMAV), which was set up to develop cutting-edge materials technologies and to support research activities and promote training for young people.

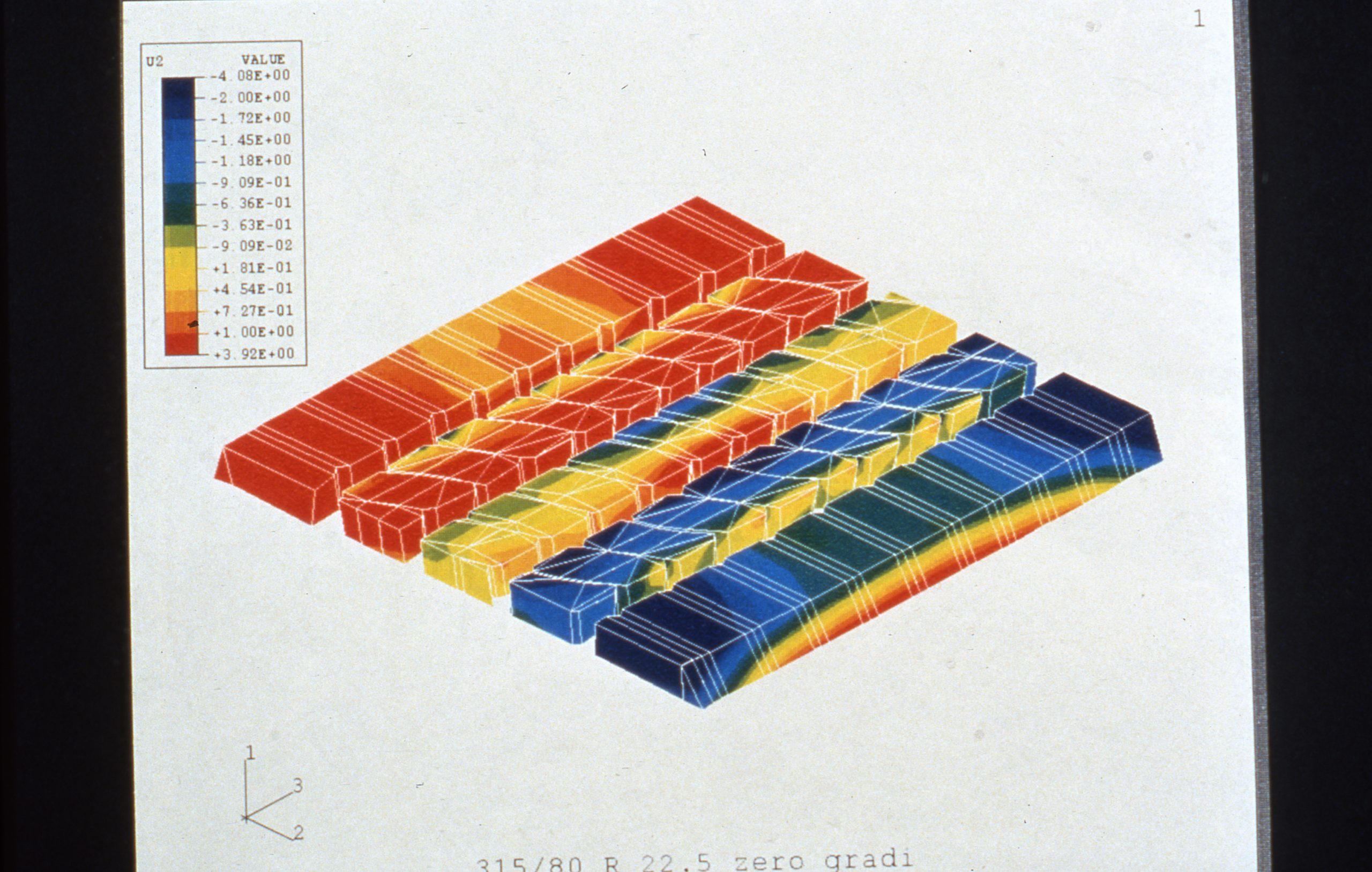

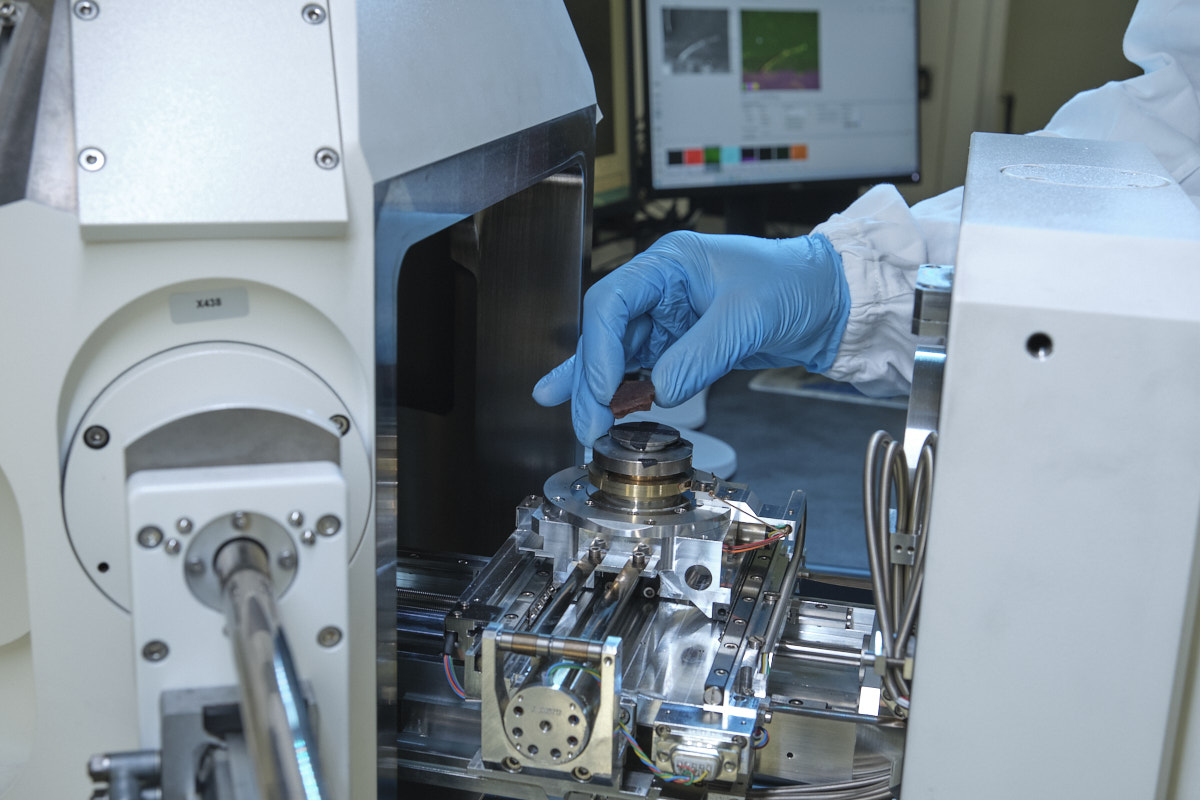

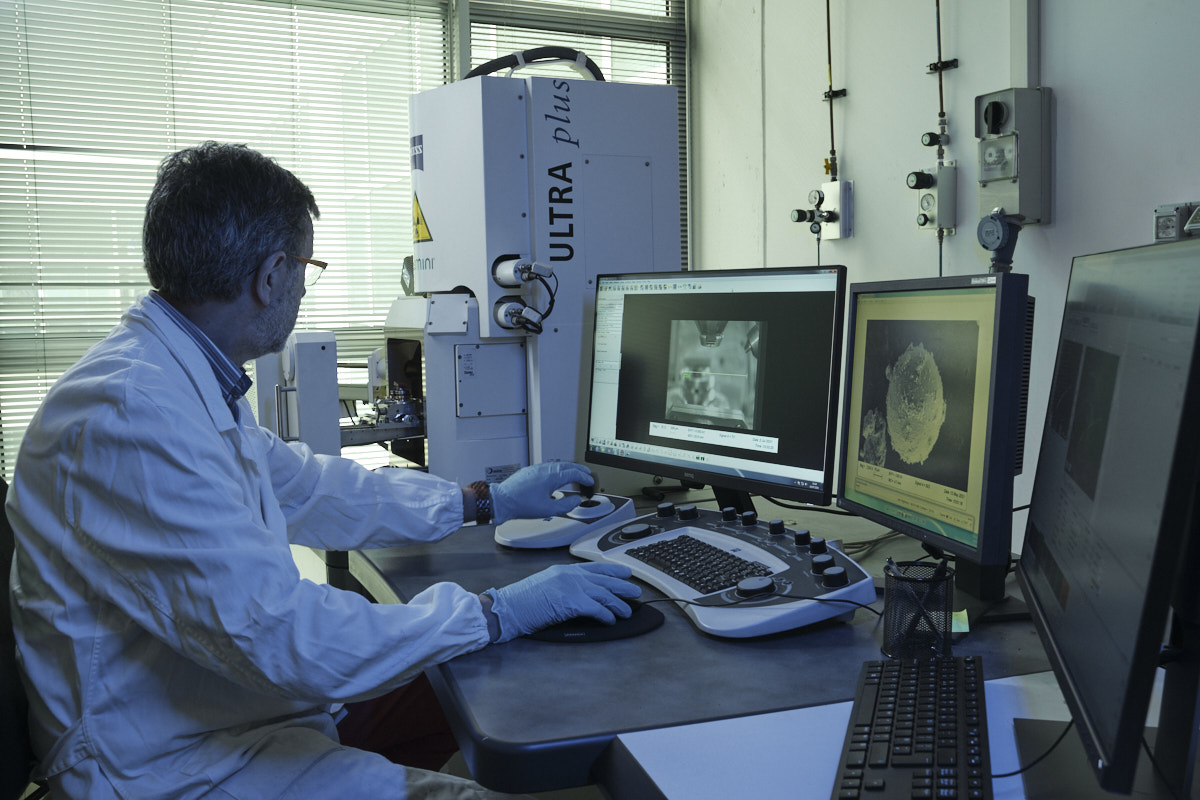

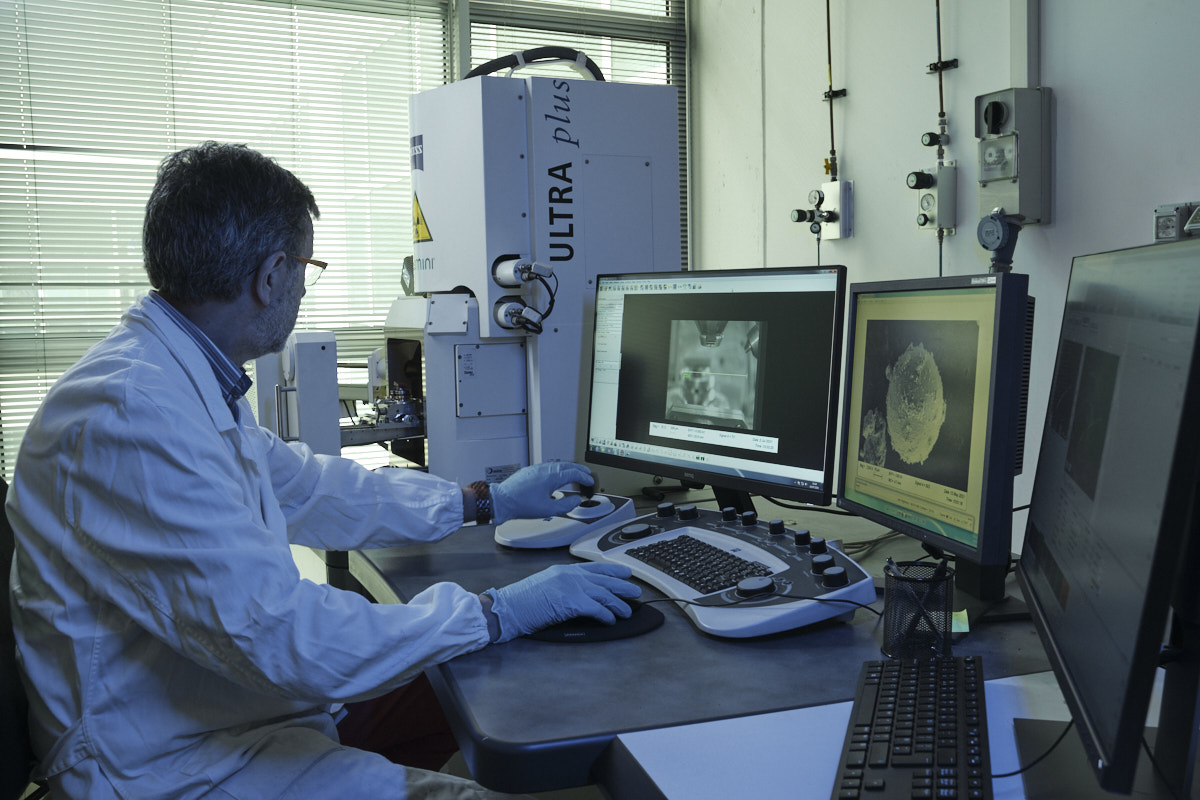

Training, research and development remain a strategic asset for Pirelli today: more than 2,000 people work in R&D across the Milan headquarters and the company’s twelve technological centres around the world, and the Group continues to work with suppliers, universities and vehicle manufacturers to anticipate technological innovation. Pirelli’s long-term goal is to replace 100% of fossil- and mineral-based raw materials with bio-based, renewable or recycled components. In addition to this, 80% of aftermarket tyres are now developed using virtual models and simulations, reducing design and production times and costs. The shift towards an increasingly sustainable industry takes time, but the direction is clear: what is research today will become reality tomorrow.

This constant drive to investigate, to go and look “inside things”, is the profound meaning of the great mosaic entitled Scientific Research, created in 1961 from a design by Renato Guttuso and preserved – significantly – in the study room of the Pirelli Foundation. Surrounded by their microscopes and calculators, the scientists imagined by the painter are intent on observing the Moon. A goal later achieved, and from which we now look further still, towards what lies beyond and cannot yet be seen, but which study, research, and the intelligence of humans and machines will one day reveal.

In the 1980s, Pirelli’s designs benefited from the use of new tools made possible by advances in computing technologies. The following decade saw the development of an important academic partnership with the creation of the Consortium for Research on Optical Switching and Processing in Milan (CoreCom) together with the Politecnico University of Milan. The Consortium soon became a European benchmark for research on optical communications, pioneering work also in networks and special optical fibres. Innovation, however, did not concern materials and products alone. In 1999, at Bicocca, Pirelli presented its Modular Integrated Robotized System (MIRSTM) for automated tyre production. Protected by twenty-two patents, it made it possible to manufacture high- and ultra-high-performance tyres in small batches with very rapid development times, ushering in new logistics and customer service possibilities. This represented a radical shift from traditional production processes. In 2001, the partnership between Pirelli and the University of Milano-Bicocca gave rise to the Consortium for Research on Advanced Materials (CORIMAV), which was set up to develop cutting-edge materials technologies and to support research activities and promote training for young people.

Training, research and development remain a strategic asset for Pirelli today: more than 2,000 people work in R&D across the Milan headquarters and the company’s twelve technological centres around the world, and the Group continues to work with suppliers, universities and vehicle manufacturers to anticipate technological innovation. Pirelli’s long-term goal is to replace 100% of fossil- and mineral-based raw materials with bio-based, renewable or recycled components. In addition to this, 80% of aftermarket tyres are now developed using virtual models and simulations, reducing design and production times and costs. The shift towards an increasingly sustainable industry takes time, but the direction is clear: what is research today will become reality tomorrow.

This constant drive to investigate, to go and look “inside things”, is the profound meaning of the great mosaic entitled Scientific Research, created in 1961 from a design by Renato Guttuso and preserved – significantly – in the study room of the Pirelli Foundation. Surrounded by their microscopes and calculators, the scientists imagined by the painter are intent on observing the Moon. A goal later achieved, and from which we now look further still, towards what lies beyond and cannot yet be seen, but which study, research, and the intelligence of humans and machines will one day reveal.